Revolutionizing Industry: Exploring the World of Digital Manufacturing

In an era defined by technological advancements, it comes as no surprise that the manufacturing industry is undergoing a significant transformation....

In the world of engineering and materials science, innovation is the driving force that pushes boundaries and shapes the future. One such innovation that has been gaining increasing attention in recent years is smart materials.

These materials possess the remarkable ability to change their properties in response to external stimuli, making them a game-changer in various industries.

In this blog, we will explore the fascinating world of smart materials, their applications, and their potential to revolutionize the way we design and build.

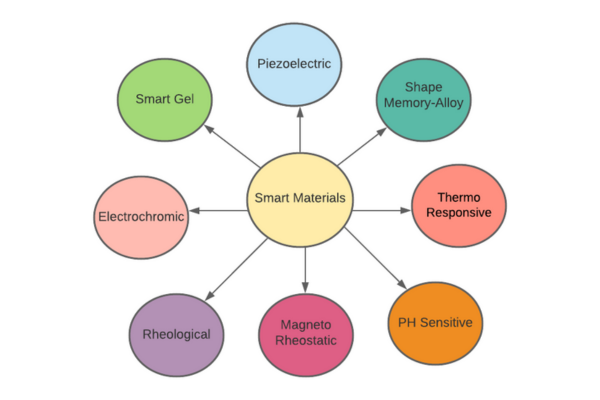

Smart materials, also known as responsive materials or intelligent materials, are a class of materials engineered to exhibit dynamic, adaptive behavior in response to specific external conditions or stimuli. These stimuli can include changes in temperature, stress, moisture, light, or electric fields.

Smart materials have the ability to sense these changes and respond to altering their properties, such as shape, color, conductivity, or mechanical strength.

There are several types of smart materials, each with its unique set of properties and applications. Here are a few notable examples:

The versatility of smart materials has led to their adoption in a wide range of application across various industries:

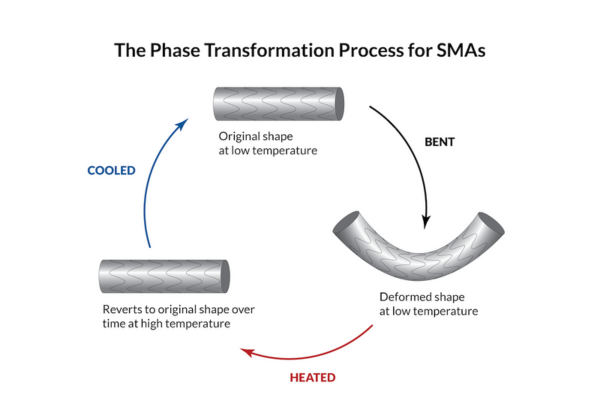

Shape Memory Alloys (SMAs) are a class of smart materials that exhibit the remarkable ability to return to a predetermined shape when subjected to a specific temperature change.

This unique property is due to a phase transition that occurs within the material. When the SMA is heated above a critical temperature, it undergoes a reversible transformation from a low-temperature, martensitic phase to a high-temperature, austenitic phase, allowing it to recover its original shape.

One of the most well-known SMAs is Nitinol, which is a nickel-titanium alloy. Nitinol has found numerous applications in various industries, including:

Piezoelectric materials are another category of smart materials that exhibit a unique property - they generate an electric charge when mechanical stress is applied to them, and, conversely, deform when an electric field is applied.

This phenomenon is known as piezoelectric effect and has a numerous practical applications:

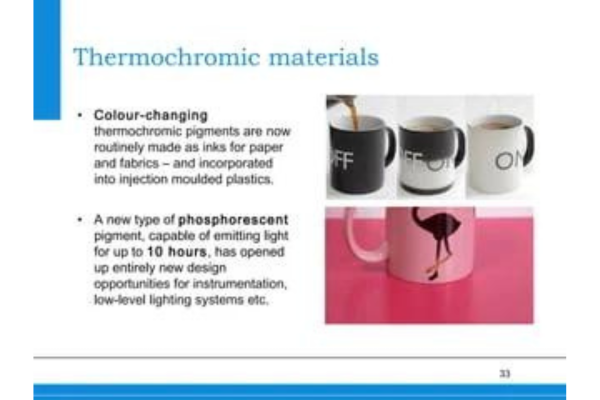

Thermochromic materials are smart materials that change color in response to changes in temperature. This property has various practical applications, particularly in areas where temperature monitoring and control are important:

While the potential of smart materials is vast, their widespread adoption comes with challenges. Cost, durability, and scalability are some of the issues that need to be addressed for further development and integration into various industries.

However, as research and development in this field continue to advance, the possibilities are limitless. Imagine buildings that can adapt to changing weather conditions, medical implants that monitor and respond to bodily functions, or clothing that adjusts its insulation based on temperature. The future of engineering with smart materials is brimming with innovation and promise.

Smart Materials represent a paradigm shift in material science and engineering. Their ability to respond intelligently to external stimuli opens a door to a wide array of applications that were once thought impossible.

As research in this field continues to evolve, we can expect to see more groundbreaking developments that will shape the way we interact with the world and revolutionize various industries.

Smart materials are not just materials; they are the building blocks of a smarter, more responsive future.

In an era defined by technological advancements, it comes as no surprise that the manufacturing industry is undergoing a significant transformation....

In an era where speed, efficiency, and sustainability are prized, the transport sector is ripe for a revolution. Enter Hyperloop technology, Elon...

OpenAI remains a leader and a force to be reckoned with in its ever-evolving environment of micro-intelligence.